How is gum made? Number the steps.

Step After the gum is cut or molded into the appropriate shape, it is lightly sprinkled with powdered sweetener to keep it from sticking to machinery or packaging.

Step High speed machines carefully wrap and package the gum in air tight wrappers. This ensures the gum is fresh and soft when you open the pack. Then the gum is shipped to stores around the world for people of all ages to enjoy.

Step If the gum is candy coated, like most gum balls or pellet gum, it is sprayed with liquid sweetener, allowed to dry and then sprayed again. This process is repeated several times until the candy shell reaches the proper thickness.

Step Powdered sugar, glucose syrup, flavoring and the other ingredients are slowly added to the gum base until the warm mix thickens like dough.

Step In a carefully temperature controlled room, the gum is cooled for up to 48 hours. This allows the gum to properly set.

Step Machines called extruders are used to blend, smooth and form the gum.

Step It's time for the gum to be shaped. Gum can be flattened and cut into sticks, or squeezed into a rope shape and cut into chunks, or molded into shapes and candy coated.

Step The gum base ingredients are melted together and filtered.

Did you know?

|

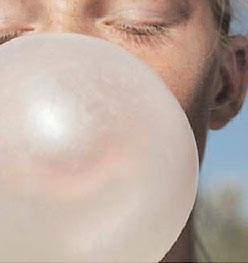

The largest bubble ever blown was 23 inches (about 58 cm) in diameter. The record was set July 19, 1994 by Susan Montgomery Williams of Fresno, CA. (Guinness Book of World Records 1998)

| |